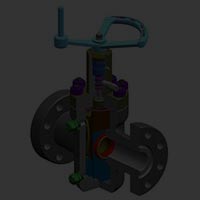

Wellhead Valves and SSV: Repair, Remanufacture and Spare Parts

Scope

Types: Gate Valve, Choke Valve, Check Valve, Plug Valve and Ball Valve

Pressure Rating: 2000, 3000, 5000 & 1000 psi

Temperature Classes: K, L, N, P, S, T, U & V

Material Classes: AA, BB & CC for General Services

DD, EE & FF for Sour Services

Product Specification Level: PSL1, PSL2 & PSL3

Performance Requirements: PR1

Standard

- API 6A

- NACE MR0175

Repair and remanufacture of wellhead valves according to API Recommended Practice 6AR

General Services

- Packings and O-rings Replacement

- Seat and Plug/ Gate Repair, Coating, Lapping or Replacement

- Stem and Ball Repair or Replacement

- Body & Bonnet Build Up by Welding, Machining and Heat Treatment (if necessary).

- Hydrotest according to API 6A

Surface Treatment

- Chrome Plating & ENP

- STELLITE, Hastelloy, Inconel and Tungsten Carbide Coating for Use in Oil, gas and Petrochemical plants

- NOREM Coating for Use in Power Plants

- Coating Processes: TIG, HVOF & PTA

Spare Parts Fabrication

- Gate, Gate Guide & Retainer Plate

- Ball

- Plug

- Stem & Stem Packing

- Seat Ring & Body Bushing

- Seal Ring and Lip Seal

- Spring Wave

SSV Actuator

- Design and simulation

- Sizing

- Manufacturing

- Test according to API 6A

- Repair and remanufacture